The tube endformer is a hydraulic machine for the expansion or reduction of tube up to 150mm diameter.

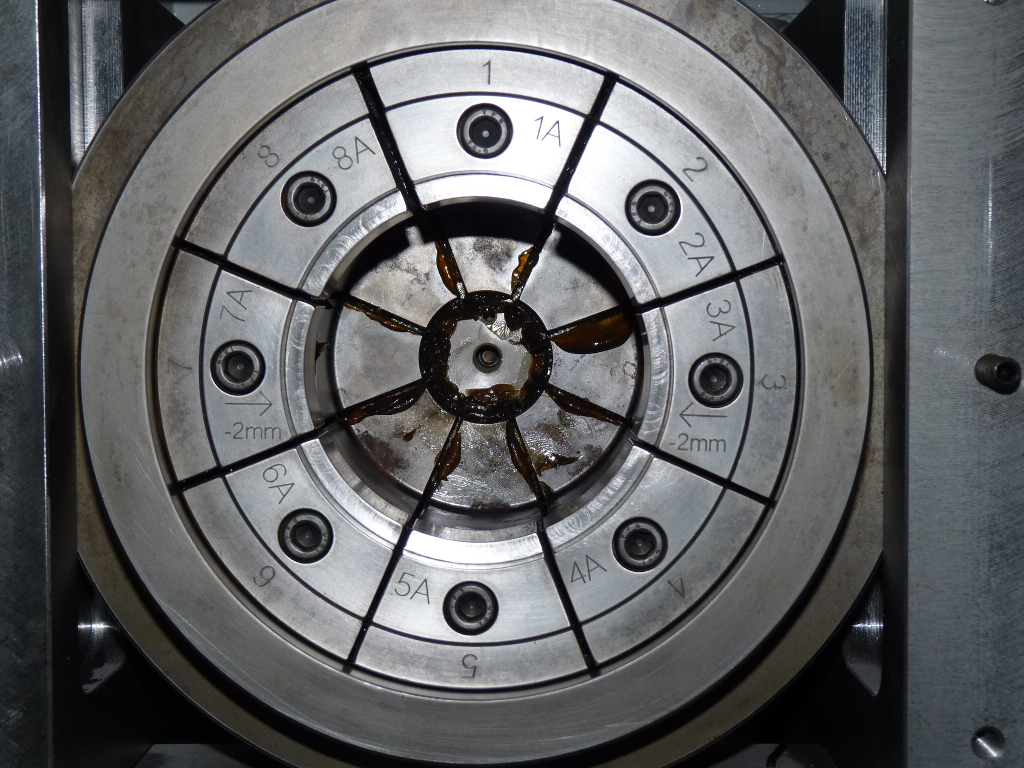

The tube forming is achieved by using the industry standard C tooling. Reducing materials by pushing a tapered set of jaws into a fixed cone; Expanding by pushing a tapered mandrel into fixed segmented fingers.

The machine features manual adjustment of the forming ram stroke via a stop nut on the back of the forming ram. A plug in foot pedal at the front of the machine controls the auto cycle.

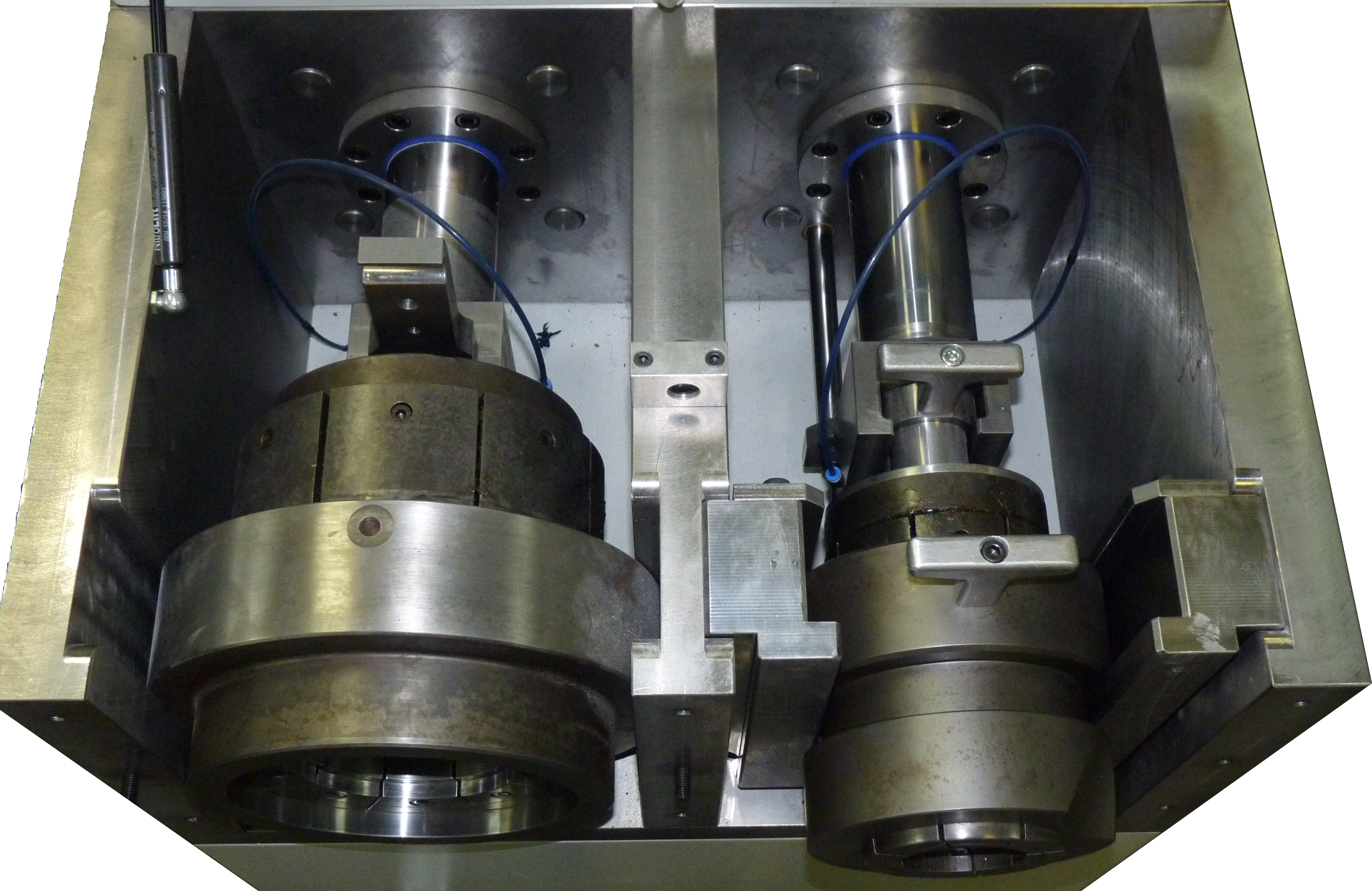

The standard machine comprises 2 head built in 1 piece to minimise overall machine width.

Options

- Oil Cooler

- Automatic tool grease (with tooling adapted)

- Electric Crane for tool lift (for 150 size machines)

- Hydraulic Motor Inverter drive for improved power consumption

- Paint colour to customer specification

Typical Specifications

Dimensions: W D H 708 X 1525 X 1500 mm

Weight: 900KG (without oil)

Oil Capacity: 178L

Motor: 7.5 KW IE3 Energy Rated (IEC standard)

Electricity Supply: 3 Phase 380/415V 32A

Safety: Schmersal SafetyPLC

Control System: Schneider Switch Gear 24V DC, Siemens S7-1200

Safety Standards: ISO 13849, ISO 12100:2010

Legal Conformity: CE